When it comes to boat building, choosing the right materials is crucial. Among the various materials available, marine plywood stands out for its durability, strength, and resistance to moisture. This is where marine plywood suppliers come into play. They provide the essential materials needed for constructing boats, ensuring quality and reliability. In this blog, we will explore the vital role that marine plywood suppliers play in the boat-building industry, discussing their contributions, the benefits of marine plywood, and what to consider when selecting a supplier.

Understanding Marine Plywood

What Is Marine Plywood?

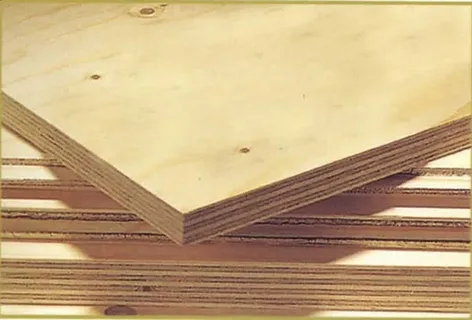

Marine plywood is a type of plywood specifically designed for use in environments exposed to moisture, such as boats, docks, and other watercraft. Unlike regular plywood, marine plywood is manufactured with waterproof adhesives and is made from high-quality wood species, making it less likely to delaminate or warp when exposed to water.

Note: Finding trusted marine plywood suppliers UAE is crucial for any project that requires sturdy, water-resistant materials. Marine plywood offers superior strength and is designed to resist rot and warping, making it ideal for use in boats, docks, and outdoor furniture. Collaborating with a reliable supplier guarantees you’ll receive the best quality products for your investment. For outstanding service and top-quality marine plywood, reach out to Maestro Global today. Let us help you with your project!

Characteristics of Marine Plywood

- Water Resistance: Marine plywood is treated with water-resistant adhesives, allowing it to withstand harsh marine conditions.

- Strength and Durability: The materials used in marine plywood are stronger than those in standard plywood, providing added durability.

- Smooth Surface Finish: The surface of marine plywood is typically smooth, making it suitable for painting and finishing.

- Lightweight: Despite its strength, marine plywood is lightweight, which is essential for boat building.

- Eco-Friendly Options: Some marine plywood suppliers offer products made from sustainable wood sources, contributing to environmental conservation.

The Importance of Marine Plywood Suppliers

1. Quality Assurance

Ensuring High Standards

Marine plywood suppliers play a critical role in ensuring that the materials they provide meet high-quality standards. They carefully select the wood used in their products, ensuring it is free from defects, knots, and other weaknesses that could compromise the integrity of the plywood.

Certification

Reputable suppliers often have their products certified by organizations that set industry standards. This certification ensures that the marine plywood is suitable for use in boat building and can withstand the challenges of marine environments.

2. Diverse Product Range

Variety of Options

Marine plywood suppliers offer a wide range of products to meet the needs of different boat builders. They provide various thicknesses, sizes, and wood species, allowing builders to choose the right plywood for their specific project.

Custom Solutions

Many suppliers also offer custom solutions, allowing boat builders to request specific dimensions or characteristics tailored to their projects. This flexibility is essential for accommodating unique designs or construction methods.

3. Technical Support and Expertise

Knowledgeable Staff

A significant advantage of working with marine plywood suppliers is the access to knowledgeable staff. Suppliers often employ experts who understand the needs of boat builders and can provide valuable advice on material selection and construction techniques.

Problem-Solving

If builders encounter challenges during construction, suppliers can offer solutions based on their experience and expertise. This support can help prevent costly mistakes and ensure the project stays on track.

Benefits of Using Marine Plywood in Boat Building

1. Enhanced Durability

Marine plywood is designed to endure the harsh conditions found in marine environments. Its resistance to water and moisture helps prevent rot and decay, prolonging the life of the boat.

2. Lightweight Design

Because marine plywood is lightweight, it is easier to handle and transport, making it a preferred choice for boat builders. This lightweight feature also contributes to the overall performance and efficiency of the boat.

3. Cost-Effective

While marine plywood may have a higher initial cost than standard plywood, its durability and longevity make it a cost-effective option in the long run. Fewer repairs and replacements are needed, ultimately saving money.

4. Aesthetic Appeal

Marine plywood has a smooth surface finish that can be painted or stained to enhance the appearance of the boat. This aesthetic appeal is essential for builders who want to create visually appealing watercraft.

What to Consider When Choosing a Marine Plywood Supplier

1. Reputation and Experience

Researching Suppliers

When selecting a marine plywood supplier, it is crucial to research their reputation and experience in the industry. Look for suppliers with positive reviews and a proven track record of providing high-quality products.

Recommendations

Ask for recommendations from other boat builders or industry professionals. Their experiences can help guide you toward reputable suppliers.

2. Quality of Products

Certifications and Standards

Check whether the supplier’s products meet industry standards and have the necessary certifications. This ensures that the marine plywood is suitable for boat building.

Product Samples

Request samples of the plywood to evaluate its quality firsthand. Inspect the plywood for defects, moisture resistance, and overall construction.

3. Range of Products

Variety and Customization

Choose a supplier that offers a diverse range of marine plywood products, including different sizes, thicknesses, and wood species. This variety allows you to find the right materials for your specific project.

Custom Orders

If your project requires specific dimensions or characteristics, ensure the supplier can accommodate custom orders. This flexibility is essential for unique boat designs.

4. Technical Support

Expert Advice

Look for suppliers that provide technical support and expert advice. Knowledgeable staff can help you make informed decisions and troubleshoot any issues that arise during the construction process.

Problem Resolution

A reliable supplier should be willing to assist you in resolving any problems that may occur with the materials or during the building process.

5. Pricing and Payment Options

Competitive Pricing

While price should not be the sole determining factor, it is essential to compare prices among different suppliers. Look for competitive pricing that aligns with your budget without compromising quality.

Payment Flexibility

Consider suppliers that offer flexible payment options. This can make managing your budget easier, especially for larger projects.

The Future of Marine Plywood Suppliers

1. Sustainability Initiatives

Eco-Friendly Products

As the demand for sustainable materials grows, marine plywood suppliers are increasingly focusing on eco-friendly options. Many suppliers now offer marine plywood made from sustainably sourced wood, which helps reduce the environmental impact of boat building.

Certification Programs

Some suppliers participate in certification programs that promote responsible forestry practices. This ensures that the wood used in their products comes from managed forests, contributing to environmental conservation.

2. Innovation in Manufacturing

Advanced Production Techniques

The marine plywood industry is also witnessing advancements in manufacturing techniques. Suppliers are adopting new technologies that enhance the production process, resulting in higher quality and more durable products.

Research and Development

Investing in research and development allows suppliers to create innovative products that meet the evolving needs of boat builders. This includes improving water resistance, strength, and aesthetic appeal.

3. Digital Transformation

Online Presence

As more businesses move online, marine plywood suppliers are establishing a robust online presence. This allows customers to easily browse products, compare prices, and place orders from the comfort of their homes or offices.

E-Commerce Platforms

Many suppliers are developing e-commerce platforms that enable customers to purchase marine plywood directly online. This convenience streamlines the purchasing process and makes it easier for builders to access the materials they need.

Conclusion

Marine plywood suppliers play a crucial role in the boat-building industry by providing high-quality materials, expert advice, and support. By understanding the importance of selecting the right supplier, boat builders can ensure they have access to the best materials for their projects. From ensuring quality assurance to offering diverse product options, marine plywood suppliers contribute significantly to the success of boat construction.

For More Insightful Articles Related To This Topic, Feel Free To Visit: blogwritting.